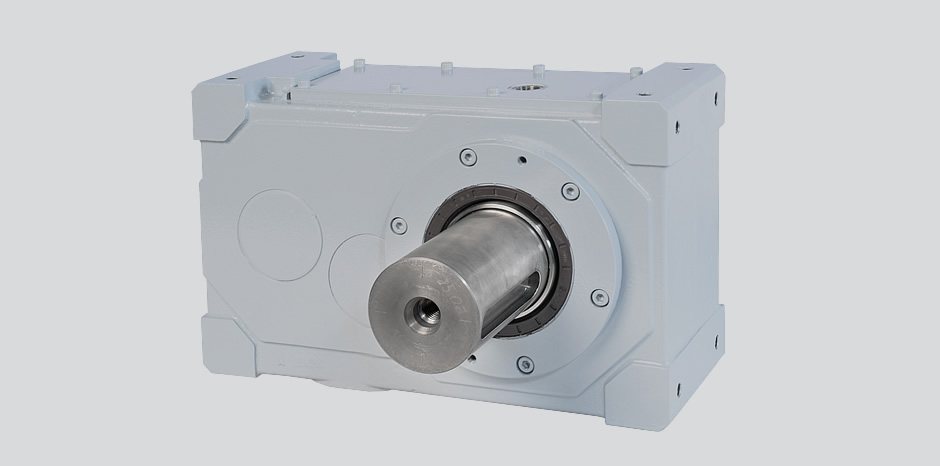

Extruder Gearboxes for Special Challenges

25 Degrees of Inclination and 10 Percent More Power

RSGetriebe has set new benchmarks in the development of extruder gearbox technology for more than 50 years now. In the course of the years, individual construction was turned into an efficient module system consisting of 15 size ranges with torques of up to 250,000 Nm. In addition to cost-efficiency, RSGetriebe’s main strengths are flexibility and clever designs. Being a member of the HerkulesGroup, the company is able to fulfill customer requirements that far exceed those of a “normal” gearbox manufacturer, such as modelmaking, welded body construction and 3D printing.

Thanks to these advantages, RSGetriebe is able to prove itself even in the most complex challenges of drive technology. A long-time Swiss customer turned to RSGetriebe with a special request. They wanted to implement gearboxes with up to 25% of inclination. At the same time, the customer wanted to transfer 10% more power. The difficulty is obvious: the transmission application is complicated by leaving the stationary mode due to lubrication and seals. RSGetriebe found the right solution – thanks to elaborate oil flow systems for toothing and bearing, flexible seals and different toothing corrections, the challenge was solved to the complete satisfaction of the customer.

This is just one example of the benchmarks that are set by RSGetriebe in extruder gearbox manufacturing.

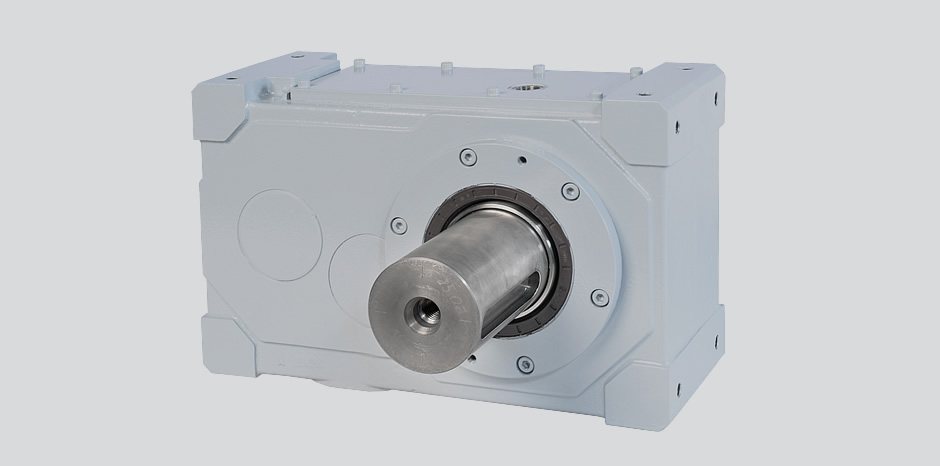

Extruder Gearboxes for Special Challenges

25 Degrees of Inclination and 10 Percent More Power

RSGetriebe has set new benchmarks in the development of extruder gearbox technology for more than 50 years now. In the course of the years, individual construction was turned into an efficient module system consisting of 15 size ranges with torques of up to 250,000 Nm. In addition to cost-efficiency, RSGetriebe’s main strengths are flexibility and clever designs. Being a member of the HerkulesGroup, the company is able to fulfill customer requirements that far exceed those of a “normal” gearbox manufacturer, such as modelmaking, welded body construction and 3D printing.

Thanks to these advantages, RSGetriebe is able to prove itself even in the most complex challenges of drive technology. A long-time Swiss customer turned to RSGetriebe with a special request. They wanted to implement gearboxes with up to 25% of inclination. At the same time, the customer wanted to transfer 10% more power. The difficulty is obvious: the transmission application is complicated by leaving the stationary mode due to lubrication and seals. RSGetriebe found the right solution – thanks to elaborate oil flow systems for toothing and bearing, flexible seals and different toothing corrections, the challenge was solved to the complete satisfaction of the customer.

This is just one example of the benchmarks that are set by RSGetriebe in extruder gearbox manufacturing.