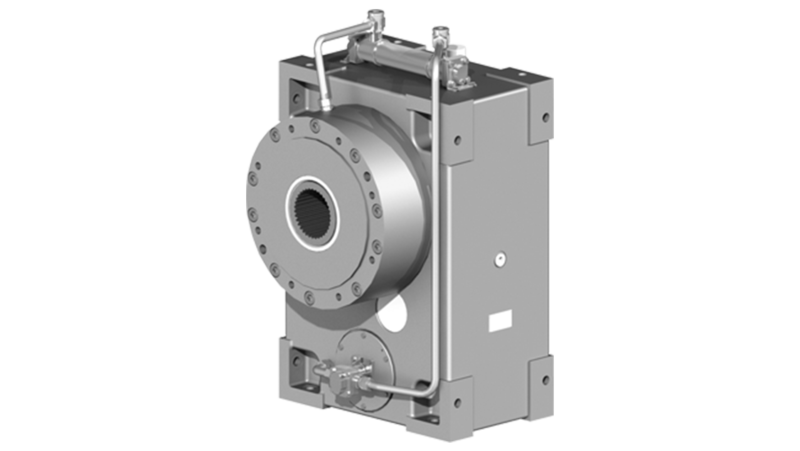

FEX Extruder Gearboxes – Single-Screw Extruders

Custom-made Extruder Gearboxes

The flat extruder gearbox of the FEX Series has been specially developed for the extrusion process in the plastics industry and for recycling plants with a view to the axial loads that occur. The gearbox – available in Z or U shape – is characterized by its high power density and compact design.

The sizes range from a centre distance of 125 to 630 mm and have been dimensioned based on the respective screw diameters. The torques of these models lie in a range of up to 200,000 Nm with freely selectable gear ratios.

A Variety of Options for Every Application

A wide variety of options is available for the FEX extruder gearboxes. Whether motor flange, coupling, or oil/water cooler – the gearboxes are ideally adapted to your application. They come complete with a thrust bearing (self-aligning roller thrust bearing) specially designed for the purpose. Screw pull-out to the front or to the rear is also individually implementable.

Additional Options:

- Reinforced thrust bearings

- Lubricant and temperature monitoring

- Drive motors

- Shaft end: smooth, profile DIN 5480, keyway, complete with connecting flange

Technical data

Precise, modular housings available in eleven sizes cover a complete range of models:

• Centre distances from 125 to 630 mm

• Models with up to 3 speeds

• Ratios from 5:1 to 100:1

• Maximum output torques up to 200,000 Nm

• Z or U form

• Eleven standard sizes, special sizes on request

• Cooling, lubrication and lubricant monitoring according to the customer's wishes

• Input and output to the customer's specifications

| Power | P | kW | 8 to 510 |

| Ratio | i |

| 5 to 100 (1 to 3-speed models) |

| Speed | n1max | min-1 | Up to 3,000 |

| Torque | T2max | Nm | Up to 200,000 |

| Centre distance | mm | 125 to 630 | |

| Form | Z or U |

| Housing | Cast iron |

| Lubrication | Oil splash lubrication, oil circulation lubrication with pump or separate oil supply unit. |

| Cooling | Oil/water cooler, internal and external, oil/air cooler |

The inputs and outputs are implemented in accordance with the customer's specifications.