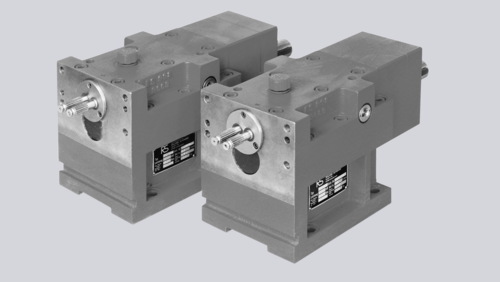

Industry Solutions

For Complex and Customized Requirements

RSGetriebe has been an established partner to a wide range of industries for many decades. Every field of industry has its own requirements and legitimacies – even in the drive technology area. The RSGetriebe team therefore uses its decades-long know-how to develop individual solutions for every industry and thus supports the success of your products.

- Drive Technology

- Construction Machinery & Building Material Machinery

- Chemical Industry

- Printing & Paper Production Technology

- Extruders, Plastics & Rubber Processing Machinery

- Woodworking Machinery

- Steelworks & Rolling Mills

- Compressor, Compressed Air & Vacuum Technology

- Foodstuffs & Packaging Machines

- Power Systems

- Testing Machinery& Test Bench Construction

- Textile Machinery

- Process Plants & Equipment

- Machine Tools & Manufacturing Systems

Back to top